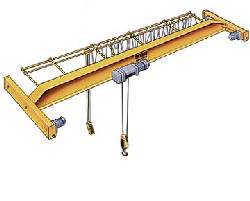

CRANES

OVERHEAD TRAVELLING

CRANES

Many different types of overhead

crane can be designed and manufactured to suit each individual site and work application- Overhead cranes can be overslung

with the end carriage wheels running on gantry rails or underslung with the crane suspended below the beams. The downshop travel can be manual push/pull, hand geared or powered by electric motors. The same choices are available for both the hoist lifting and travel motions. Single girder cranes with a standard hoist unit are economically priced but for very high capacities or

reduced headroom it may be necessary to have double beam cranes with crab mounted hoisting units. In addition to overhead cranes, Goliath or Semi Goliath rail

mounted floor cranes can be manufactured and installed.

Crane lifting capacities are almost unlimited but the most popular models are up to 5 or 1 0 tonnes.

JIB CRANES

Both

floor and wall mounted jib cranes can be supplied with capacities up to 5 tonnes. A range of slewing angles up to 360 degrees

can be designed. Jib cranes are usualyy operated manually but for very heavy applications power slewing is available. They

can be supplied with or without hand, electric or pneumatic hoist units.

MOBILE GANTRIES

“Fixed

height mobile gantries”, standard bracing or outrigged for maximum hoist travel.

Side frames are usually of an 'A' frame configuration and support the appropriate

'1' beam for the safe working load of the gantry. A choice of castors is available, either cast iron or robust polyurethane.

Adjustable

gantries are very similar design but allow for a sliding centre extension piece within the frame.

Self-erecting

gantries provide far greater flexibility as they can easily be moved and erected in different sites.